Mechanical seals and gland seals are two common types of sealing devices used in various industries to prevent fluid leakage from pumps, mixers, and other equipment. Both seals have their advantages and disadvantages, and the choice between them depends on several factors. In this article, we will compare mechanical seals and gland seals and help you determine which one is the better choice for your application.

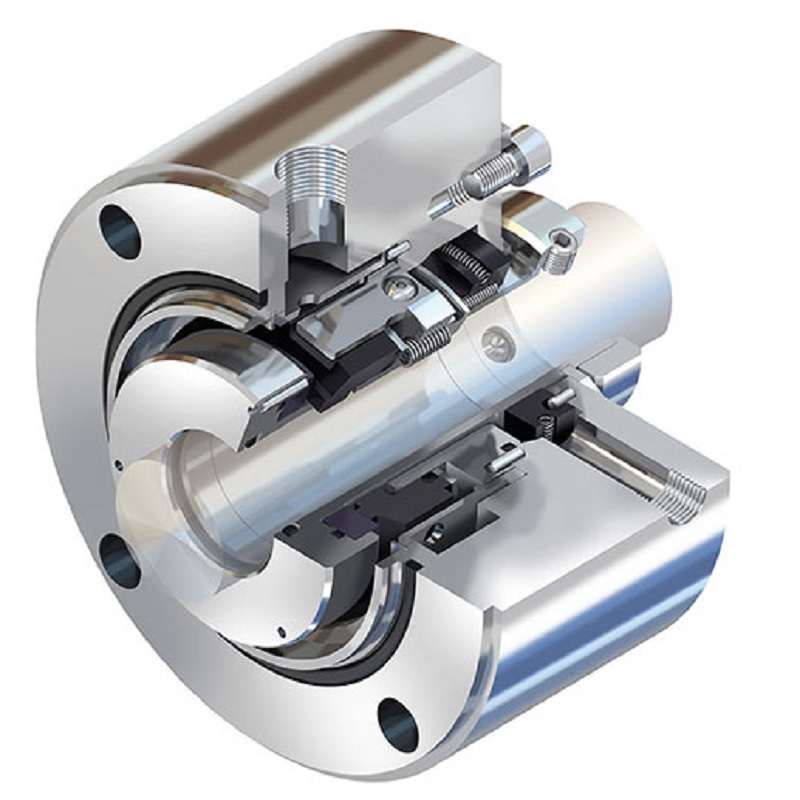

Section 1: What is a Mechanical Seal?

A mechanical seal is a device that creates a static seal between two surfaces in relative motion, such as a rotating shaft and a stationary housing. It consists of two main components: a rotating seal face and a stationary seal face. The seal faces are held together by a spring and a set of secondary seals, which prevent fluid leakage. Mechanical seals are commonly used in high-pressure and high-temperature applications, where gland seals may not be effective.

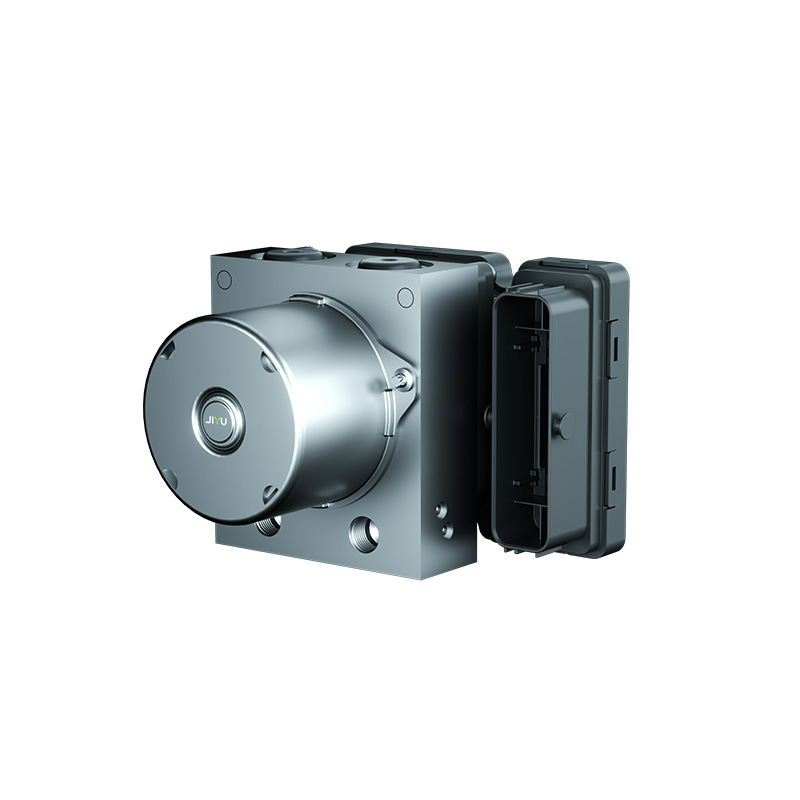

Section 2: What is a Gland Seal?

A gland seal, also known as a packing seal, is a device that uses a packing material, such as braided or molded graphite, to create a dynamic seal between a rotating shaft and a stationary housing. The packing material is compressed by a gland follower, which creates a seal between the shaft and the housing. Gland seals are commonly used in low-pressure and low-temperature applications, where mechanical seals may be too expensive or unnecessary.

Section 3: Advantages and Disadvantages of Mechanical Seals

Mechanical seals offer several advantages over gland seals, including higher reliability, longer service life, and better sealing performance. They are also more resistant to wear and tear, which reduces maintenance costs. However, mechanical seals are more expensive than gland seals and require more complex installation and maintenance procedures. They are also more prone to failure if not properly installed or maintained.

Section 4: Advantages and Disadvantages of Gland Seals

Gland seals offer several advantages over mechanical seals, including lower cost, simpler installation and maintenance procedures, and better compatibility with a wider range of fluids. They are also more forgiving of shaft misalignment and vibration, which reduces the risk of seal failure. However, gland seals have a shorter service life than mechanical seals and may require more frequent replacement. They are also less effective at preventing fluid leakage, especially in high-pressure and high-temperature applications.

Section 5: Which is the Better Choice?

The choice between mechanical seals and gland seals depends on several factors, including the application, the fluid being pumped, the operating conditions, and the budget. In general, mechanical seals are the better choice for high-pressure and high-temperature applications, where reliability and sealing performance are critical. Gland seals are the better choice for low-pressure and low-temperature applications, where cost and simplicity are more important than sealing performance.

Conclusion:

Mechanical seals and gland seals are both effective sealing devices that can prevent fluid leakage from pumps, mixers, and other equipment. The choice between them depends on several factors, including the application, the fluid being pumped, the operating conditions, and the budget. By understanding the advantages and disadvantages of each type of seal, you can make an informed decision and choose the best option for your specific needs.