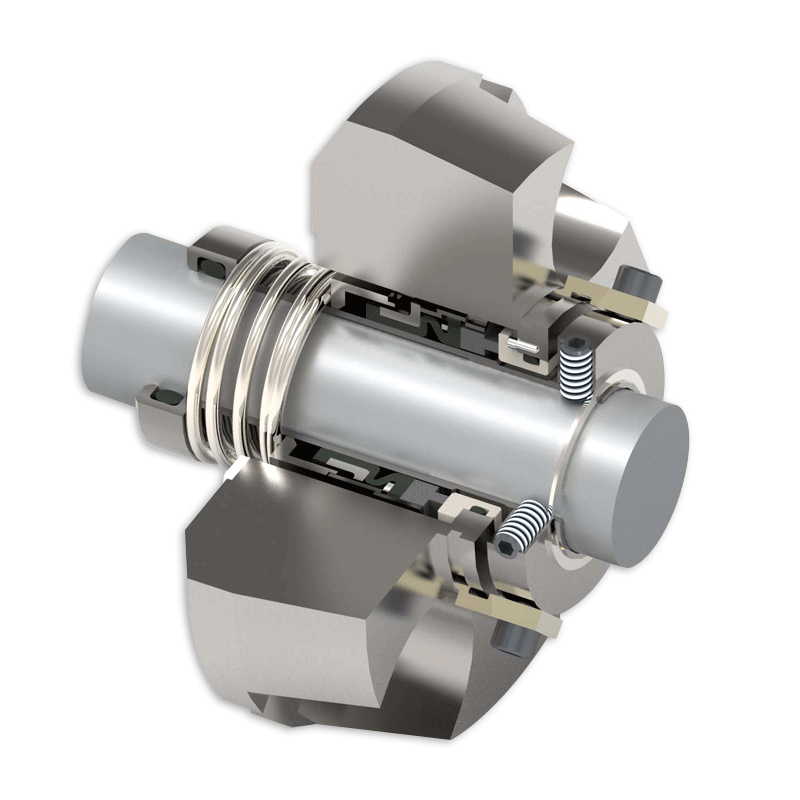

Mechanical seals are critical components in many industrial applications, including pumps, compressors, and mixers. They prevent leakage of fluids and gases, ensuring safe and efficient operation. There are two main types of mechanical seals: dry seals and wet seals. In this article, we will explore the differences between these two types of seals and their benefits.

Section 1: What is a Dry Seal?

A dry seal is a mechanical seal that operates without any external fluid or lubrication. It relies on a self-lubricating material, such as carbon or graphite, to create a seal between the rotating and stationary parts. Dry seals are commonly used in applications where the process fluid is abrasive, corrosive, or contains solids that can clog the seal faces.

Section 2: What is a Wet Seal?

A wet seal, on the other hand, requires a continuous flow of fluid to lubricate and cool the seal faces. The fluid can be the same as the process fluid or a separate lubricating fluid. Wet seals are typically used in applications where the process fluid is clean and non-abrasive, and the seal faces require constant cooling.

Section 3: Differences between Dry and Wet Seals

The main difference between dry and wet seals is the need for external fluid or lubrication. Dry seals operate without any external fluid, while wet seals require a continuous flow of fluid. Dry seals are more suitable for applications where the process fluid is abrasive, corrosive, or contains solids that can clog the seal faces. Wet seals are more suitable for applications where the process fluid is clean and non-abrasive, and the seal faces require constant cooling.

Section 4: Benefits of Dry Seals

Dry seals offer several benefits over wet seals. They are more reliable and require less maintenance since they do not rely on an external fluid for lubrication. They also have a longer lifespan since they are not subject to wear and tear from the fluid. Dry seals are also more energy-efficient since they do not require a pump to circulate the fluid.

Section 5: Benefits of Wet Seals

Wet seals also offer several benefits over dry seals. They provide better cooling and lubrication, which can extend the life of the seal faces. They are also more forgiving of misalignment and vibration since the fluid can compensate for these issues. Wet seals are also more suitable for applications where the process fluid is clean and non-abrasive.

Conclusion:

In summary, dry seals and wet seals are two types of mechanical seals that offer different benefits depending on the application. Dry seals are more suitable for abrasive, corrosive, or solid-laden fluids, while wet seals are more suitable for clean and non-abrasive fluids. Both types of seals have their advantages and disadvantages, and the choice depends on the specific application requirements.