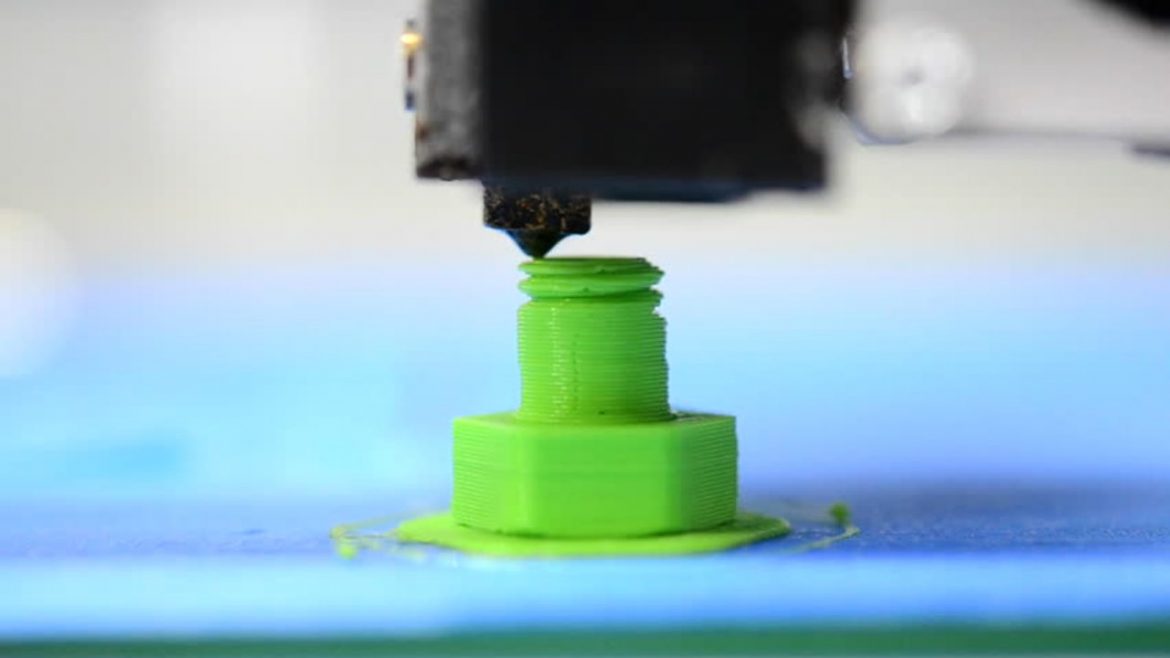

In the realm of 3D printing, where innovation knows no bounds, the materials used play a crucial role in determining the quality, durability, and cost of the final product. While there is a wide range of materials available for 3D printing, today we delve into the realm of exclusivity and luxury, exploring the most expensive 3D printing materials that push the boundaries of creativity and craftsmanship. From precious metals to advanced composites, let's embark on a journey to discover the pinnacle of 3D printing materials.

- Titanium: The Lightweight Marvel:

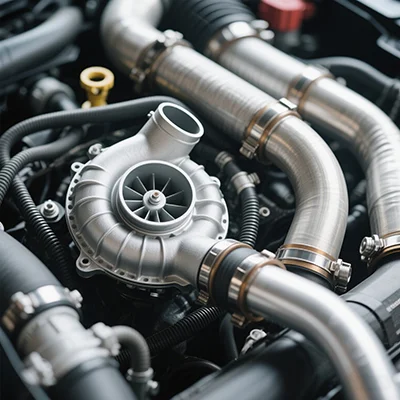

Titanium, renowned for its exceptional strength-to-weight ratio, finds its place at the forefront of high-end 3D printing materials. With its remarkable corrosion resistance and biocompatibility, titanium is widely used in aerospace, medical, and automotive industries. The cost of titanium powder, the primary material used in 3D printing, is significantly higher compared to other metals, making it one of the most expensive options for additive manufacturing. - Precious Metals: The Epitome of Elegance:

For those seeking the epitome of luxury and opulence, 3D printing with precious metals such as gold, silver, and platinum offers unparalleled possibilities. These materials not only add a touch of exclusivity to jewelry and decorative items but also find applications in high-end engineering and prototyping. The cost of precious metal powders, coupled with the intricate printing processes involved, contributes to their status as some of the most expensive 3D printing materials available. - Carbon Fiber Composites: Strength Refined:

When it comes to combining strength, lightness, and durability, carbon fiber composites reign supreme. These materials, composed of carbon fibers embedded in a matrix, offer exceptional mechanical properties and are widely used in industries such as aerospace, automotive, and sports equipment. The intricate manufacturing processes involved in producing carbon fiber composites, along with the high cost of raw materials, make them a premium choice for 3D printing applications. - High-Performance Polymers: Engineering Excellence:

High-performance polymers, such as PEEK (Polyether Ether Ketone) and ULTEM (Polyetherimide), are revolutionizing the world of 3D printing with their exceptional thermal and chemical resistance, mechanical strength, and flame retardancy. These materials find applications in industries that demand superior performance, such as aerospace, medical, and automotive. The cost of high-performance polymer filaments, combined with the specialized printing requirements, positions them as some of the most expensive 3D printing materials.

Conclusion:

As 3D printing continues to evolve, the demand for high-quality, specialized materials grows. The most expensive 3D printing materials, including titanium, precious metals, carbon fiber composites, and high-performance polymers, offer unparalleled possibilities in terms of strength, elegance, and engineering excellence. While the cost of these materials may be prohibitive for some, they represent the pinnacle of craftsmanship and innovation in the world of additive manufacturing. As technology advances and new materials emerge, the boundaries of what is possible in 3D printing will continue to be pushed, opening up new avenues for creativity and exploration.