Graduated scales are essential tools in surveying, engineering, and scientific measurement. Their precision and accuracy are critical for ensuring reliable data collection, whether it’s determining land boundaries, constructing buildings, or conducting scientific experiments. Behind their seemingly simple appearance lies a complex interplay of mechanics, materials, and calibration that allows these instruments to deliver consistent and precise results.

This article explores the principles behind graduated scales, the mechanics that govern their accuracy, and how companies like Hangzhou Runhe Surveying Instrument Co., Ltd. leverage decades of experience in producing high-quality surveying instruments to ensure reliability and performance.

What Are Graduated Scales?

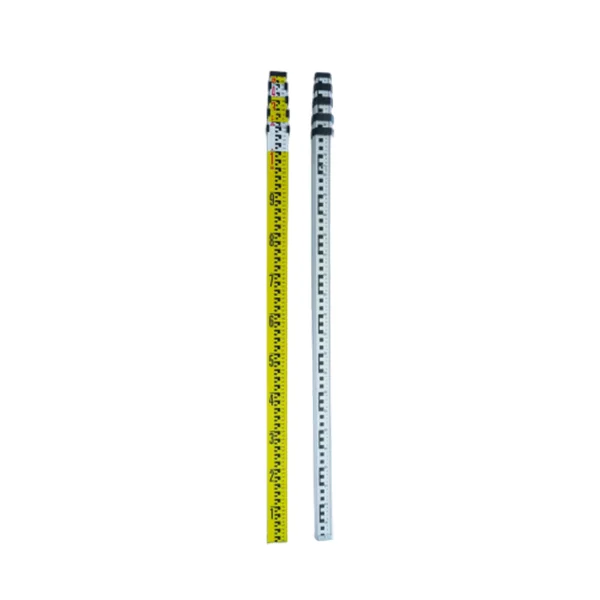

Graduated scales, sometimes referred to as vernier scales or graduated rulers, are measurement devices marked with a series of lines or divisions that indicate units of measure. These scales allow surveyors, engineers, and scientists to quantify distances, angles, or other parameters with a high degree of accuracy.

Types of Graduated Scales:

Linear Scales – Used to measure straight-line distances.

Angular Scales – Common in theodolites and total stations for measuring angles.

Vernier Scales – Offer enhanced precision by allowing readings between the smallest marked divisions.

Digital Graduated Scales – Modern instruments incorporate electronic readings for enhanced accuracy and ease of use.

Graduated scales are commonly used on instruments like levels, theodolites, tripods, and specialized surveying rods. Hangzhou Runhe Surveying Instrument Co., Ltd. produces high-quality tripods, leveling rods, centering rods, and RTK-specific carbon fiber rods to support these instruments.

The Mechanics Behind Precision

The precision of a graduated scale depends on several mechanical factors:

1. Material Quality

The stability and durability of the scale material are crucial. Materials such as aluminum alloys, stainless steel, or carbon fiber are chosen for their low thermal expansion, resistance to corrosion, and mechanical stability. Hangzhou Runhe uses high-grade materials for its RTK carbon fiber rods and other measuring instruments, ensuring minimal deformation and consistent accuracy over time.

2. Scale Marking and Engraving

Precision engraving or printing of scale divisions is fundamental. Any deviation or imperfection in the markings can introduce measurement errors. Advanced engraving techniques and quality control processes are used to achieve highly accurate markings.

3. Vernier Mechanisms

Vernier scales enhance resolution by allowing users to read fractions of the smallest scale division. The interaction between the main scale and the vernier requires meticulous alignment and precise mechanical tolerances. Even minor misalignment can reduce the effective precision of the instrument.

4. Calibration

Regular calibration ensures that scales maintain their accuracy over time. Calibration compensates for mechanical wear, environmental factors, and potential human error during manufacturing. Companies like Hangzhou Runhe maintain strict quality control and calibration protocols to guarantee instrument reliability.

Applications of Graduated Scales in Surveying

Graduated scales are integral to a variety of surveying instruments and applications:

Land Surveying – Linear and angular scales are used to measure distances and angles for mapping and property boundaries.

Construction Engineering – Accurate leveling and angle measurement are essential for building foundations, bridges, and infrastructure projects.

Topographic Mapping – High-precision instruments equipped with graduated scales help capture terrain variations accurately.

Geodesy and Cartography – Measurements of earth curvature and mapping coordinates rely on precision scales.

Hangzhou Runhe Surveying Instrument Co., Ltd. supports these applications by providing durable, high-precision tripods, leveling rods, and specialized accessories that enhance the functionality and accuracy of graduated scales.

Advances in Graduated Scale Technology

The evolution of graduated scales has been driven by the need for higher precision, durability, and user convenience:

1. Carbon Fiber Rods

Lightweight yet rigid, carbon fiber rods are resistant to thermal expansion, making them ideal for RTK (Real-Time Kinematic) surveying. Hangzhou Runhe specializes in producing these rods to maintain accuracy in field measurements.

2. Digital Integration

Modern surveying instruments incorporate digital sensors to read graduations electronically. This reduces human reading errors and allows seamless integration with mapping software.

3. Enhanced Marking Techniques

Laser engraving and other advanced marking methods ensure that scale divisions remain precise, even under harsh environmental conditions.

4. Modular and Adjustable Components

High-quality tripods, centering rods, and leveling supports allow surveyors to achieve perfect alignment and positioning, which directly impacts the accuracy of graduated scales.

Quality Control and Reliability

Precision is not achieved solely through design; it requires rigorous quality control. Hangzhou Runhe Surveying Instrument Co., Ltd. emphasizes strict quality management, from material selection to final inspection. Each tripod, rod, and leveling accessory is tested for mechanical stability, alignment accuracy, and durability.

The company’s development philosophy, “Bold Exploration, Quality First, Meeting New User Needs,” ensures that its instruments are reliable, long-lasting, and capable of meeting evolving surveying requirements. Long-term partnerships with clients reflect the company’s commitment to service and consistent product performance.

Practical Tips for Using Graduated Scales

Maintain Clean Surfaces – Dust or debris on scales can lead to reading errors. Regular cleaning ensures accuracy.

Check for Wear – Inspect scales and vernier mechanisms for mechanical wear that could affect precision.

Use Stable Supports – Tripods and rods should be secure and stable to prevent measurement errors.

Environmental Considerations – Temperature fluctuations can affect scale materials; carbon fiber rods and low-expansion metals mitigate these effects.

Regular Calibration – Periodic calibration ensures long-term accuracy and reliability.

By following these best practices, surveyors can maximize the precision and lifespan of their graduated scales.

Conclusion

Graduated scales are foundational tools in surveying, engineering, and scientific measurement. Their precision relies on careful material selection, meticulous engraving, precise mechanical alignment, and ongoing calibration. Companies like Hangzhou Runhe Surveying Instrument Co., Ltd. combine decades of experience, advanced manufacturing techniques, and rigorous quality control to produce tripods, leveling rods, centering rods, and carbon fiber accessories that support high-precision measurements.

Understanding the mechanics of graduated scales is essential for anyone in surveying or engineering. With the right instruments, materials, and practices, professionals can achieve accurate, reliable measurements that form the basis for successful projects and scientific research.

www.runhesurveying.com

Hangzhou Runhe Surveying Instrument Co., Ltd.