The global manufacturing landscape is undergoing a transformation where precision, speed, and flexibility define competitiveness. At the center of this shift is the integration of turntable processing with automation and robotics, a combination that accelerates workflows and sets new standards for efficiency in metalworking.

Driving Efficiency Through Turntable Processing

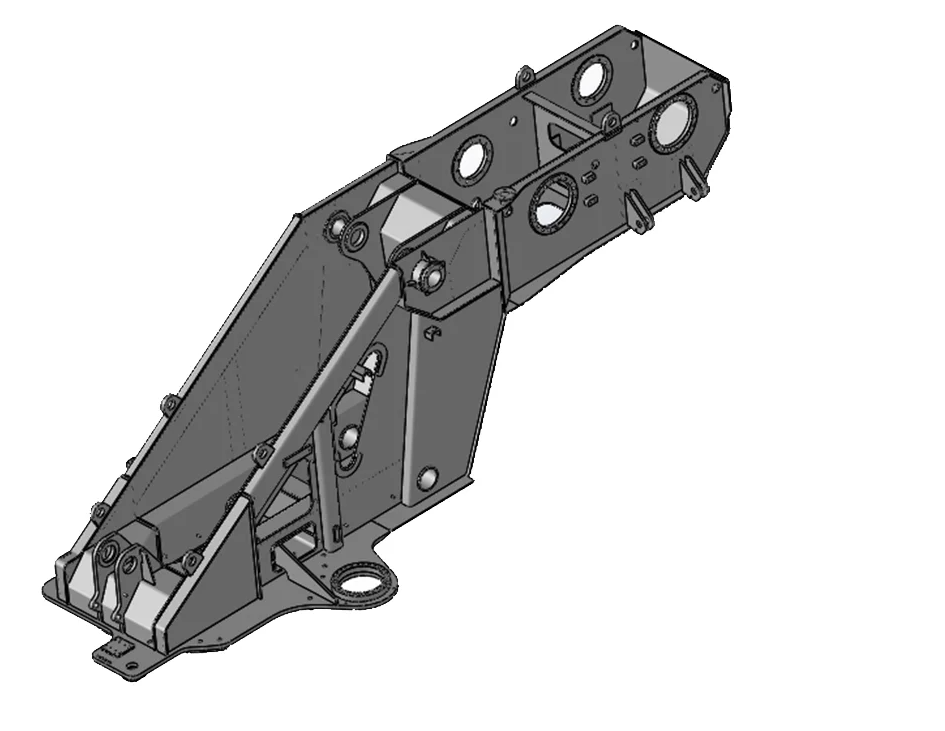

Turntable processing enables simultaneous multi-angle machining, welding, or coating on a single platform. When paired with automated systems, it eliminates unnecessary repositioning, reduces downtime, and ensures consistency in high-volume production. For industries such as construction machinery, agricultural equipment, and automotive components, this means faster throughput without compromising accuracy.

Robotics Enhancing Precision and Safety

By linking turntable platforms with robotic welding, cutting, and bending, manufacturers achieve repeatable precision that manual methods cannot match. Robotic arms working on synchronized turntables can perform laser cutting, plasma cutting, and CNC machining seamlessly, minimizing defects and maximizing material utilization. Additionally, automation reduces operator exposure to high-risk environments, improving overall workplace safety.

Digitalization and Smart Factory Integration

Turntable systems become even more powerful when connected to digital factory networks. Automated monitoring and data collection enable predictive maintenance, real-time production tracking, and AI-driven quality control. This aligns perfectly with the goals of smart factory development, where flexibility and scalability are critical.

Hengli’s Vision for Next-Generation Metal Processing

Hengli is committed to building a fully digitized and automated industrial chain, integrating turntable processing, robotics, and advanced metalworking technologies. With services spanning laser cutting, forming, welding, CNC machining, powder coating, and galvanizing, Hengli provides end-to-end solutions that meet the evolving needs of global industries.

By embedding automation and robotics into turntable-based workflows, Hengli not only improves operational efficiency but also sets a benchmark for precision manufacturing in sectors ranging from energy to special vehicles.

Conclusion

The future of metalworking lies in seamless integration—turntable processing combined with automation and robotics. This approach enhances productivity, ensures consistent quality, and prepares manufacturers for the era of smart factories. With its comprehensive capabilities and commitment to digital innovation, Hengli is shaping this future and delivering intelligent solutions across the global metal supply chain.

www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd.