Introduction

In today’s heavy industries, durability is not just a feature — it’s a necessity. Whether you're manufacturing mining equipment, construction machines, or structural frames, the strength and reliability of your components directly affect operational performance. That’s where high-quality frame welding enhances equipment durability. A strong weld doesn’t just hold metal together — it holds your entire production line together. At Hengli, we understand the critical role frame welding plays in machinery performance. With professional techniques and a commitment to excellence, we help customers build longer-lasting, more reliable equipment.

1. Why Frame Welding Quality Matters More Than Ever

Frame welding isn’t just about fusing metal components — it’s about creating a foundation that withstands repeated stress, vibration, and load-bearing pressure. Poor welding can lead to structural fatigue, cracks, and premature failures. In contrast, high-quality frame welding ensures consistent load distribution, high tensile strength, and structural integrity, especially for machinery operating in demanding sectors like mining, construction, and aerospace.

At Hengli, we don’t settle for “good enough.” Every weld is executed with precision and inspected for long-term resilience. We believe that well-executed welding is the difference between short-term fixes and long-term value.

2. Applications in the Mining Industry: The Need for Strength and Precision

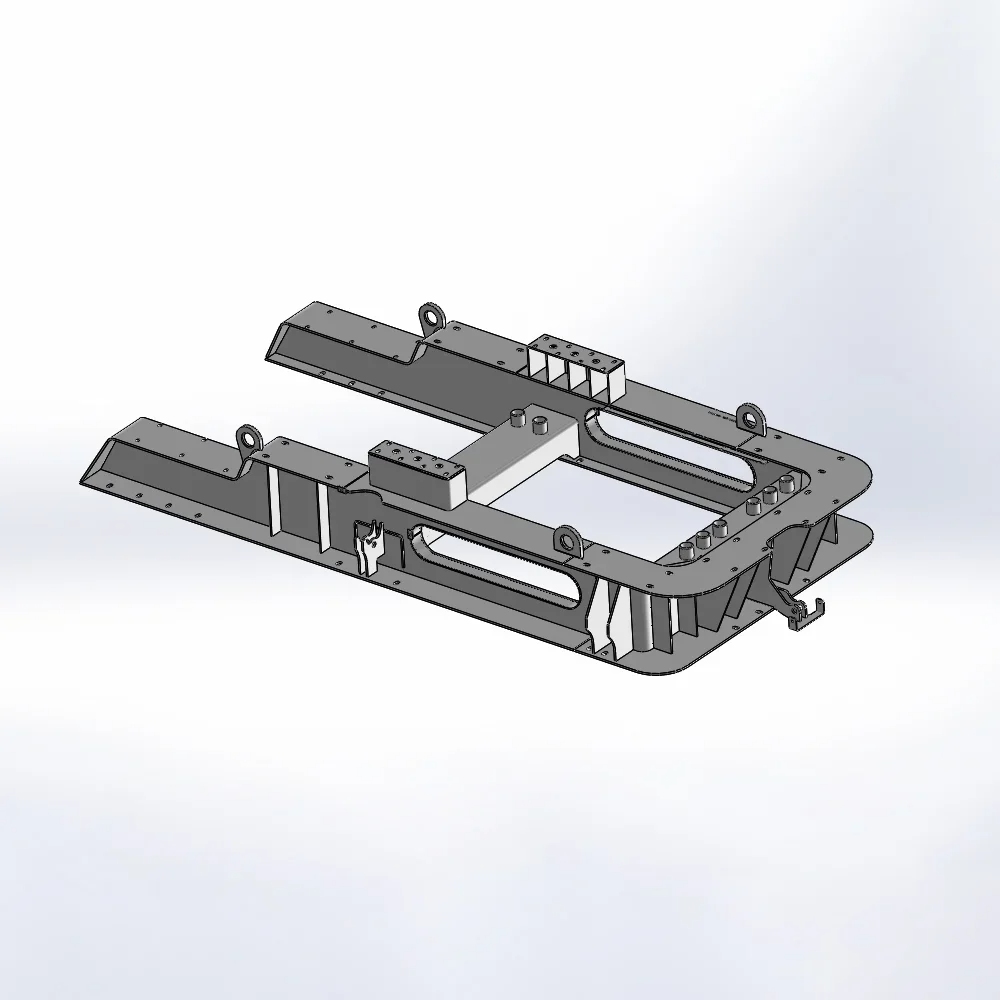

The mining industry is one of the harshest environments for equipment. Machines face high impact, extreme weight, and constant motion. That’s why frame welding for mining machinery must be precise, robust, and fatigue-resistant.

Hengli provides welding solutions for heavy-duty parts like track frames and half frames that are crucial in large mining equipment. These components need to resist dynamic forces, pressure fatigue, and environmental wear. By using techniques like MIG and TIG welding, combined with surface treatments like painting and anti-corrosion coating, we make sure your frames last in the toughest conditions.

3. Techniques That Deliver Durability

Not all welding techniques are suitable for every application. At Hengli, our engineers evaluate your project’s mechanical demands, material composition, and environment before choosing the right process. We offer:

-

MIG Welding – Excellent for thick metals and large-scale fabrication

-

TIG Welding – High precision, ideal for lighter or sensitive components

-

Spot Welding – Fast and effective for sheet structures or assemblies

But welding is only part of the solution. Our profile cutting, bending, machining, and painting services create a seamless workflow where every step supports the next. The result? A frame that isn’t just welded — it’s engineered for longevity.

4. Materials and Equipment: Built to Last

Frame durability is directly tied to material quality and welding precision. Hengli works with steel, aluminum, alloy steel, and titanium, selecting the right material based on your project’s structural and environmental needs.

To ensure accuracy, we rely on advanced welding stations and CNC-integrated platforms. Our use of robotic welding arms and digital monitoring allows for repeatable quality, reduced human error, and clean, consistent seams.

This combination of smart equipment and skilled technicians gives us full control over quality from start to finish — a major factor in ensuring long-term equipment durability.

5. Customized Welding Solutions for Unique Projects

No two machines are alike — and neither are their frames. That’s why we offer customized frame welding services for every client. Whether you're building a one-off prototype or managing high-volume production, our team can adapt to your specifications.

We work closely with your engineers to understand performance expectations, weight loads, movement points, and stress zones. Our flexible system supports both batch production and tailored solutions, helping clients get exactly what they need — no compromise.

6. Quality Control and Inspection: No Compromise

A strong weld means nothing without verification. At Hengli, quality assurance is embedded in every step of production. Our inspection system includes:

-

Visual testing for weld continuity and finish

-

Ultrasonic and radiographic testing for internal integrity

-

Load simulations to verify structural strength under real-life conditions

We follow international standards and maintain strict internal protocols. This dedication to quality control ensures that each frame meets — and often exceeds — client expectations.

Conclusion

In every industrial application, high-quality frame welding enhances equipment durability — and that means fewer breakdowns, less downtime, and longer service life. At Hengli, our welding solutions are built on precision, experience, and cutting-edge technology. Whether you're in mining, construction, or manufacturing, we help you build equipment that lasts. If you want frames that don’t just function but endure, talk to our team today. With Hengli, durability starts at the weld.

www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd.