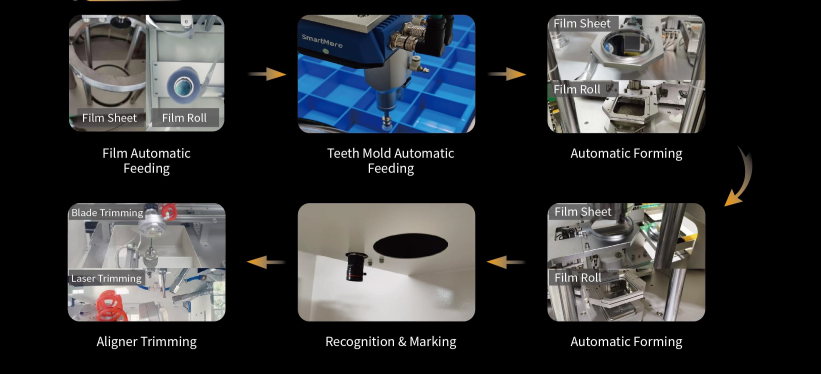

The rapid growth of the invisible aligner market is putting immense pressure on manufacturers. Traditional, labor-intensive methods are becoming a major bottleneck to scaling, quality, and profitability. Here are the top 5 pain points and how smart automation provides the solution.

Pain Point 1: Inconsistent Quality & Limited Customization

Manual handling introduces variability, leading to inconsistencies in fit and finish. Automated systems with integrated vision recognition and flexible laser cutting eliminate human error. This ensures every aligner has a transparent, smooth finish and perfect fit, directly enhancing patient comfort and treatment efficacy.

Pain Point 2: Unsustainable Labor Costs & Low Profit Margins

Relying on skilled technicians for tasks like loading models and trimming aligners is costly and limits scalability. Our automated solution features material and model auto-loading systems that can run continuously for up to an hour unattended. This dramatically reduces labor costs and increases your profit margins.

Pain Point 3: Inability to Track, Trace, and Improve

Without data, process optimization is guesswork. Our production lines integrate laser marking and barcode reading systems to create a unique data identifier for each calibrator. This enables full traceability for quality control and provides the data needed for continuous process improvement.

Pain Point 4: Poor Thickness Uniformity and Fit

Achieving uniform membrane thickness and a precise fit with manual thermoforming is challenging. Our high-precision thermoforming and proprietary cutting software guarantee exceptional thickness consistency and cutting accuracy, which are critical for predictable treatment outcomes.

Pain Point 5: Compliance Risks from Uncertified Production

Partnering with uncertified suppliers poses significant regulatory risks. Our entire solution is CE certified, and our production system complies with ISO 9001:2015. We ensure that the equipment and the production process itself meet international safety and quality standards.

Why Choose Our Automated Production Line?

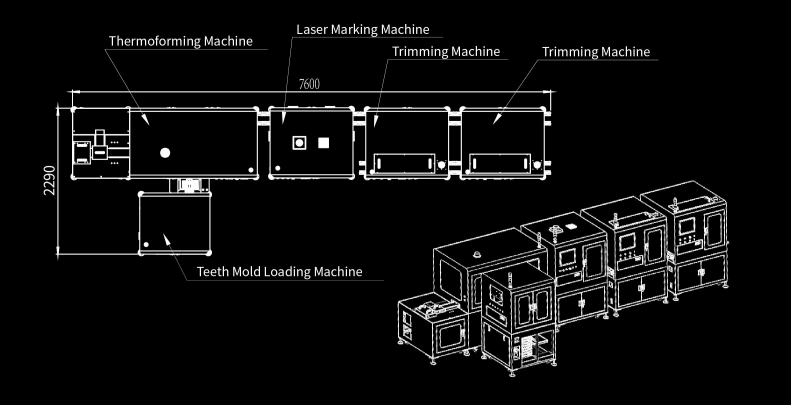

End-to-End Solution: A seamless workflow from film to finished aligner.

Modular Flexibility: Machines can be configured into a full line or used individually, allowing you to scale capacity as your business grows.

Proven Global Expertise: Our technology is trusted by manufacturers in over 20 countries, with 100+ successful automation projects delivered.

Higher Quality Consistency: Automated processing machines delivers high precision and quality consistency based on AI-driven trimming software to elevate your branding.

www.conversighttech.com

ConverSight Technology Limited