When it comes to installing metal siding, the choice of materials and techniques can significantly impact both the aesthetic appeal and functional longevity of a structure. Among the various components that contribute to a successful metal siding installation, the J channel stands out as a crucial element. This article delves into the importance of J channels in metal siding applications, exploring their functions, installation techniques, and best practices to ensure optimal performance.

Understanding J Channels in Metal Siding

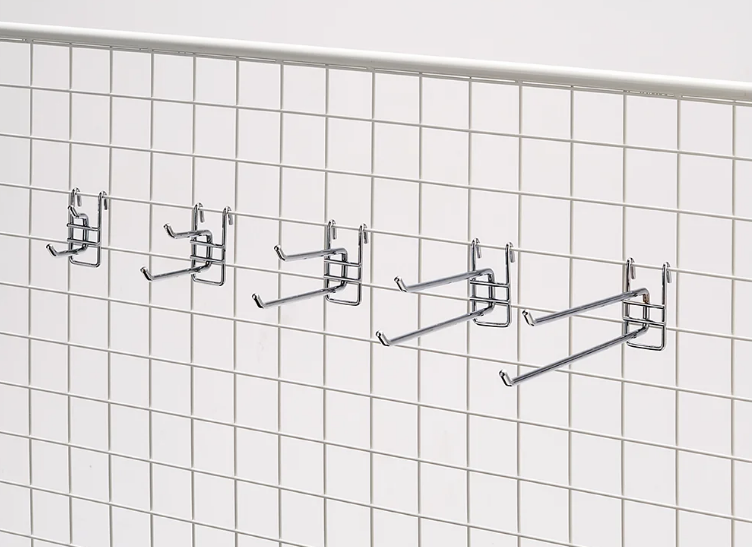

J channels are specialized trim pieces that serve multiple purposes in metal siding installations. Typically made from the same material as the siding—such as aluminum or galvanized steel—these channels are designed to provide a clean, finished edge to the siding panels. Their name derives from their distinctive J shape, which allows them to effectively cradle the edges of the siding while also facilitating water drainage and preventing moisture accumulation.

The Multifaceted Functions of J Channels

- Aesthetic Appeal: One of the primary functions of J channels is to enhance the visual appeal of metal siding. By providing a smooth transition between panels and around windows, doors, and corners, J channels create a polished look that elevates the overall design of the building.

- Moisture Management: Properly installed J channels play a vital role in managing moisture. They help direct water away from the siding and underlying structures, reducing the risk of water infiltration and subsequent damage. This is particularly important in regions prone to heavy rainfall or snow.

- Structural Support: J channels also provide structural support to the siding panels. By securing the edges of the panels, they help maintain alignment and prevent warping or buckling over time. This is essential for ensuring the longevity of the siding and the integrity of the building envelope.

- Ease of Installation: The design of J channels simplifies the installation process. They allow for easier alignment and fastening of the siding panels, making it possible for both professional contractors and DIY enthusiasts to achieve a high-quality finish.

Installation Techniques for J Channels

To maximize the effectiveness of J channels in metal siding applications, it is essential to follow best practices during installation. Here are some key steps to consider:

- Preparation: Before installation, ensure that the wall surface is clean, dry, and free from any debris. This will help create a solid foundation for the J channels and siding panels.

- Measuring and Cutting: Accurate measurements are crucial. Cut the J channels to the appropriate lengths, allowing for any necessary overlaps at corners or joints. Use a metal snip or a saw designed for cutting metal to achieve clean edges.

- Securing the J Channels: Begin by fastening the J channels to the wall using corrosion-resistant screws. Ensure that they are level and aligned properly. It is advisable to space the screws according to the manufacturer’s recommendations, typically every 12 to 16 inches.

- Installing the Siding Panels: Once the J channels are in place, proceed with the installation of the metal siding panels. Slide the edges of the panels into the J channels, ensuring a snug fit. Secure the panels according to the manufacturer’s guidelines, taking care not to overtighten screws, which can lead to panel distortion.

- Sealing and Finishing: After the siding is installed, apply a high-quality sealant around the edges of the J channels to further enhance moisture resistance. This step is particularly important in areas where the siding meets windows, doors, or other openings.

Best Practices for Long-Term Performance

To ensure the long-term performance of J channels and metal siding, consider the following best practices:

- Regular Inspections: Periodically inspect the J channels and siding for signs of wear, damage, or moisture infiltration. Address any issues promptly to prevent more significant problems down the line.

- Proper Maintenance: Keep the siding clean and free from debris. Regular washing can help maintain the appearance and functionality of the siding and J channels.

- Choose Quality Materials: Invest in high-quality J channels and siding materials that are resistant to corrosion and weathering. This will enhance the durability and lifespan of your installation.

Conclusion

In conclusion, the use of J channels in metal siding installations is not merely a cosmetic choice; it is a critical component that contributes to the overall performance, durability, and aesthetic appeal of the siding system. By understanding the functions of J channels and adhering to best practices during installation, homeowners and contractors can ensure that their metal siding projects stand the test of time. Whether you are embarking on a new construction project or renovating an existing structure, don’t overlook the importance of J channels in achieving a successful metal siding installation.