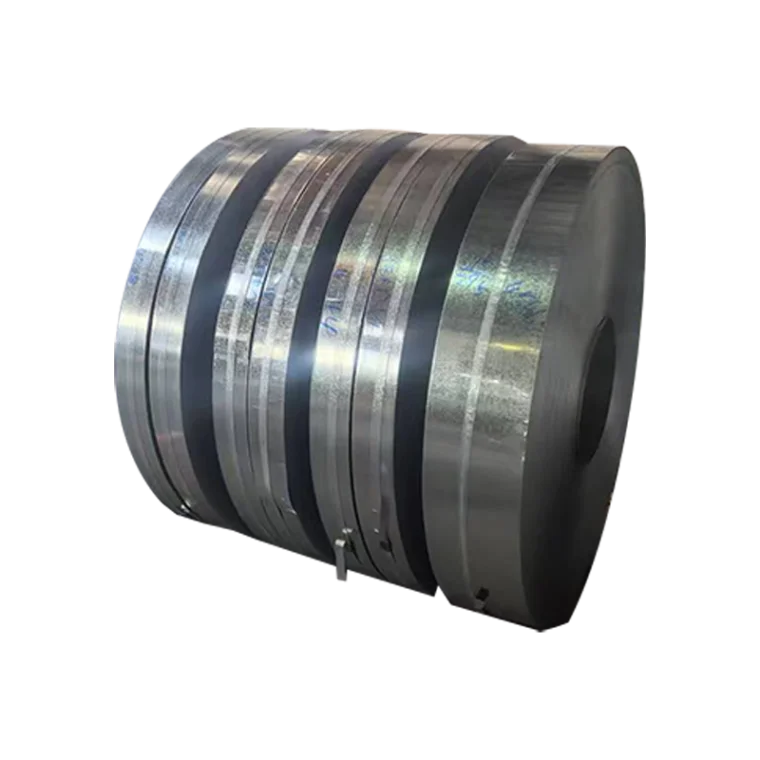

Galvanized steel coil is a versatile and durable material used in industries ranging from construction and automotive to home appliances and infrastructure. Its zinc coating provides superior corrosion resistance, making it an excellent choice for projects that demand both strength and longevity. However, not all galvanized steel coils are the same — selecting the right type for your specific application is key to achieving optimal performance and cost-effectiveness.

As a professional metal products supplier, Fuchuan Metal Co., Ltd. specializes in the research, production, and sales of stainless steel coils, plates, pipes, high-temperature alloys, Hastelloy, nickel-based alloys, aluminum, and copper products. With our products widely applied in chemical, petroleum, synthetic fiber, paper-making, natural gas, nuclear power, heat exchangers, shipbuilding, food machinery, environmental protection, construction, and aerospace industries, we understand the importance of selecting the right material for every project.

Here’s a guide to help you choose the right galvanized steel coil for your needs.

1. Understand the Two Main Types of Galvanizing

-

Hot-Dip Galvanized Steel Coil (HDG): Produced by immersing steel in molten zinc, creating a strong, corrosion-resistant coating. Ideal for outdoor applications and heavy-duty environments.

-

Electro-Galvanized Steel Coil (EG): Uses electroplating to apply a thinner, smoother zinc coating. Suitable for applications that require excellent surface finish, like automotive panels or appliances.

2. Determine the Required Coating Thickness

The thickness of the zinc layer, measured in grams per square meter (g/m²), affects corrosion resistance.

-

Thin coatings (Z100–Z275): Suitable for indoor or short-term outdoor use.

-

Thick coatings (Z350 and above): Recommended for harsh outdoor environments or marine applications.

3. Consider the Base Metal Quality

The strength, ductility, and chemical composition of the steel substrate influence performance. High-strength steel bases are essential for structural applications, while more formable grades work better for complex shaping and bending.

4. Evaluate Surface Finish and Aesthetics

If your project requires visible, decorative surfaces, choose galvanized steel coils with a smooth, uniform finish. Electro-galvanized coils often offer superior appearance, while hot-dip galvanized coils provide a more rugged, spangled look.

5. Match the Coil to Your Application Environment

-

Construction: Roofing, wall panels, structural components — prioritize corrosion resistance and load-bearing capacity.

-

Automotive: Focus on surface smoothness and paint adhesion.

-

Industrial Equipment: Balance durability, machinability, and cost.

6. Work with a Reliable Supplier

Partnering with an experienced supplier ensures you receive consistent quality and expert guidance. At Fuchuan Metal Co., Ltd., our technical team helps customers select the right galvanized steel coil specifications based on performance requirements, budget, and industry standards.

Final Thoughts

Choosing the right galvanized steel coil involves considering galvanizing method, coating thickness, base metal grade, surface finish, and intended application. With the right selection, you can ensure long-term durability, excellent performance, and cost efficiency for your project.

For expert advice and a wide range of high-quality galvanized steel products, Fuchuan Metal Co., Ltd. is your trusted partner — delivering materials that meet the strict demands of industries worldwide.

www.fuchuansteel.com

Fuchuan Metal Co., Ltd.